2024-09-12

2024-09-12 China adds 1 billion square meters of civil buildings every year, and the proportion of building energy consumption to total energy consumption continues to rise, from 10% in 1978 to 30% today. Faced with this severe challenge, vigorously developing energy-saving buildings has become a consensus among all sectors of society. The "China Thermal Insulation Material Market Survey Report" clearly points out that building thermal insulation materials are the key to improving energy efficiency, enhancing living environment, and functionality.

Global thermal insulation materials are developing towards high efficiency, energy saving, thin layer, insulation, waterproofing and external protection integration. While developing new thermal insulation materials and structural insulation and energy-saving technologies, there is a greater emphasis on targeted use of thermal insulation materials, designing and constructing according to standard specifications, and striving to improve insulation efficiency and reduce costs. Research on thin-layer thermal insulation coatings has been conducted both domestically and internationally. Several companies in the United States have already produced this type of insulation ceramic coating, such as SPM Thermo Shield, Ceramic Cover from Thermal Protective Systems, and Therma Cover from J.H. International.

However, in China, traditional insulation materials such as rock wool, glass wool, and expanded perlite still dominate the market. Despite their low price, these materials have many drawbacks: high density, poor thermal insulation performance (thermal conductivity of 0.065-0.090W/m · K), significant material loss due to thick laying, high moisture absorption, and insufficient seismic and environmental performance. These traditional materials are no longer able to meet increasingly stringent energy-saving standards, and some materials such as asbestos and glass wool contain harmful substances that pose a threat to human health.

In contrast, the market share of new insulation materials in China is only 40%. Compared with traditional insulation materials, it has low thermal conductivity, good insulation effect, light weight, low water absorption rate, good chemical stability, and easy construction. However, due to the relatively high price of new insulation materials, their widespread use in China is limited. More than 95% of newly constructed buildings in China are still high energy consuming buildings, mainly due to the widespread use of traditional insulation materials. Therefore, increasing the production and application of new insulation materials is the key to reducing building energy consumption and improving energy efficiency.

The new insulation material uses nano ceramic hollow microspheres, silicon aluminum fibers, and various reflective materials as raw materials, with a temperature resistance range of -80 to 1800 ℃, and can directly face flames for insulation. Its thermal conductivity is as low as 0.03W/m · K, which can effectively suppress and shield the radiation of infrared rays and the conduction of heat. The insulation suppression efficiency can reach about 90%, which can suppress the thermal radiation and heat loss of high-temperature objects. It can effectively cool low-temperature objects and suppress the cooling loss caused by environmental radiation heat, and also prevent the occurrence of object condensation. This material is developed based on the working principle of NASA controlling the heat conduction of space shuttles. It is suitable for high-pressure spraying, pollution-free, and has good properties such as heat radiation resistance, thin layer insulation, waterproof and anti-corrosion.

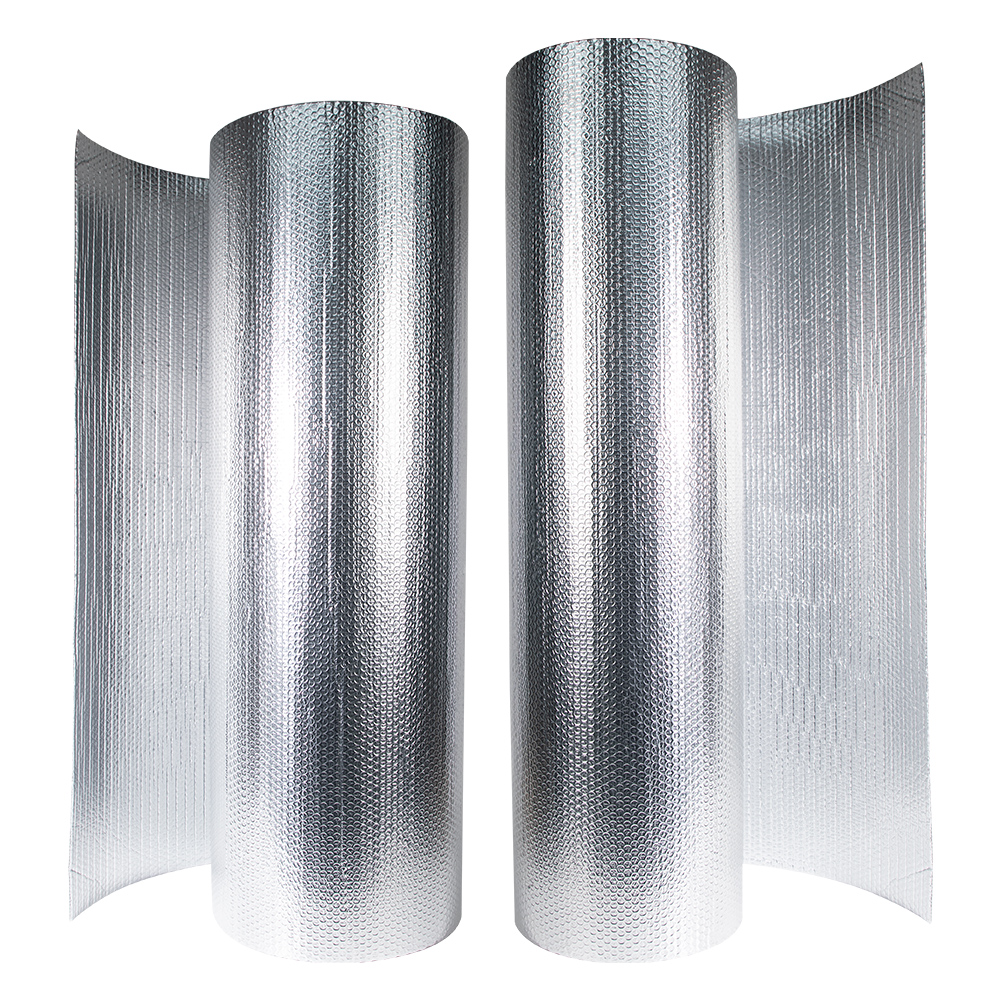

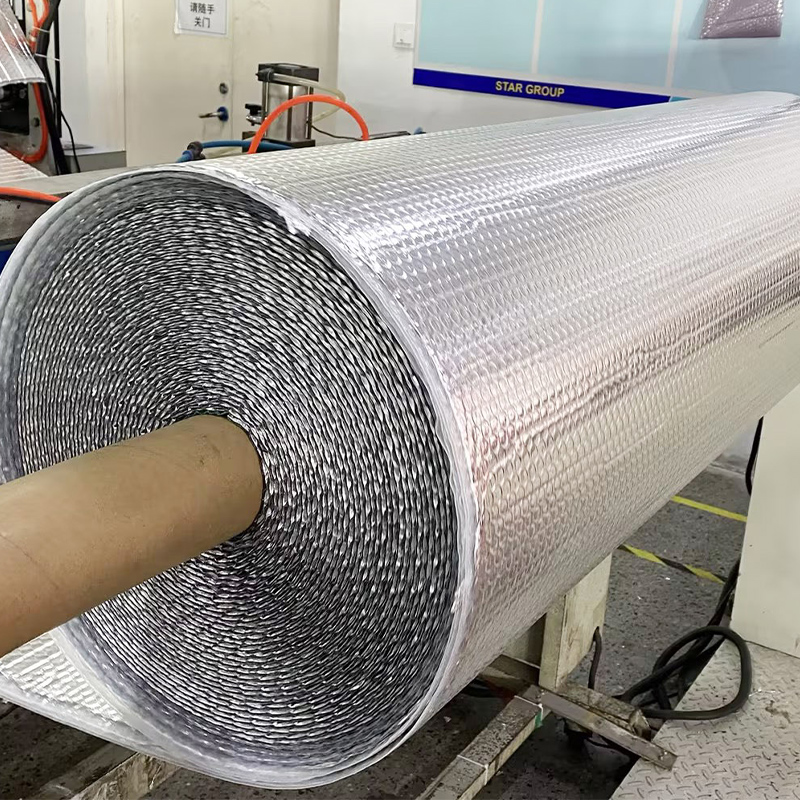

Xingchen New Thermal Insulation Material adopts a composite sandwich structure design, with aluminum foil multi-layer composite materials on both the inner and outer surfaces, and PE polyethylene airbag bubbles/XPE foam in the middle layer. This inorganic material has properties, porous fiber structure, and extremely low thermal conductivity, which can achieve long-term insulation effect.

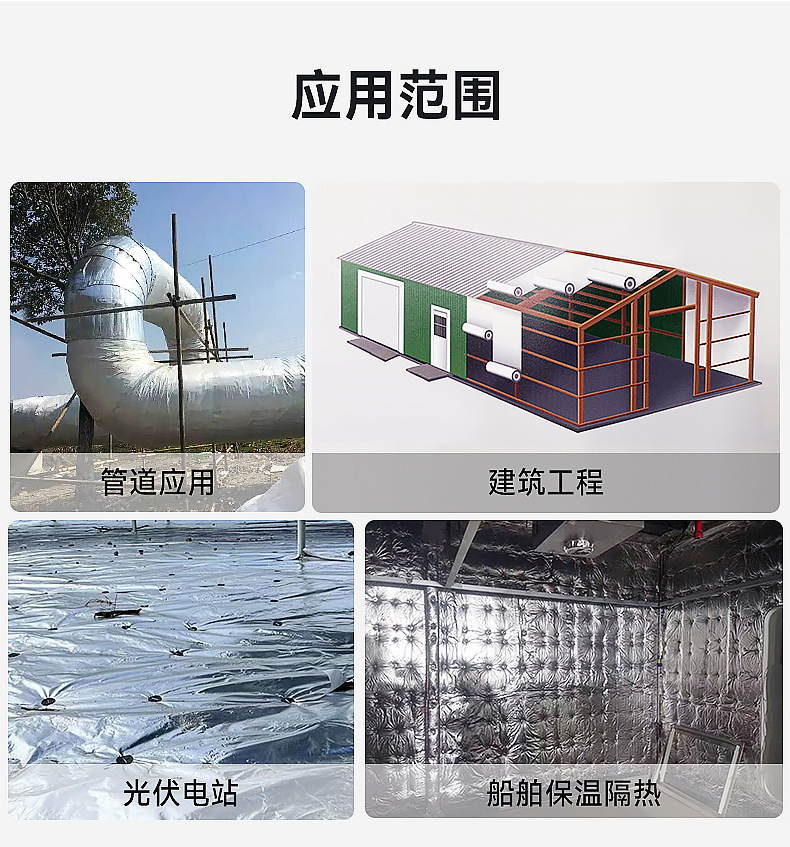

It has excellent barrier performance, excellent moisture resistance and insulation effect, and has excellent insulation, heat reflection, and thermal insulation properties. Even if heat penetrates the inner aluminum foil layer and reaches the middle PE airbag layer, heat convection will still form in the middle layer, making it difficult to penetrate the outer aluminum foil layer and effectively blocking heat transfer. The composite application of this thin-layer thermal insulation reflective coating and porous materials can be widely used in various occasions such as buildings, pipelines, vehicles, photovoltaic power stations, petrochemical oil tank equipment, grain depots, cold storage, containers, etc.

In addition, the new insulation material uses water as a dilution medium and does not contain volatile organic solvents, which is harmless to human health and the environment. Meanwhile, its production cost is only 1/5 of similar foreign products. Therefore, we call on everyone to strengthen their understanding of new thermal insulation materials and promote their application in the construction field to improve building energy efficiency.

“推行环保包装,让环保包装无处不在”是星辰的企业使命,向建筑领域输出优良的保温隔热材料,为低碳社会贡献力量是星辰义不容辞的责任。