2024-09-12

2024-09-12 1. Introduction to Lithium Battery Materials

The raw materials for battery cells mainly include electrolytes, separators, positive and negative electrode materials, etc. Lithium ions use positive electrode (cathode), negative electrode (anode), and electrolyte as conductors. The positive electrode is metal oxide, and the negative electrode is usually graphite or carbon powder.

The positive electrode material is the main source of lithium ions in lithium-ion batteries, and the positive electrode material of power batteries is the shortcoming of their energy density. At present, the successfully developed and applied positive electrode materials mainly include lithium cobalt oxide, lithium iron phosphate, lithium manganese oxide, ternary materials nickel cobalt manganese oxide, and nickel cobalt aluminum oxide.

Lithium cobalt oxide is the first commercial positive electrode material and can be considered the most mature positive electrode material for lithium-ion batteries. Lithium cobalt oxide has the advantages of high discharge plateau, good cycling performance, and simple synthesis process. However, the material contains highly toxic cobalt elements, making it difficult to ensure safety when making large power batteries. It is currently the preferred choice for small lithium batteries, and is widely used in 3C batteries.

Lithium iron phosphate is the earliest technology route adopted in China and one of the widely concerned positive electrode materials. Its main characteristics are the absence of harmful elements, low cost, excellent safety, long cycle life, but the disadvantage is low energy density. Therefore, it is mostly used in electric buses and a small number of passenger vehicles.

Lithium manganese oxide has abundant raw material resources, low cost, and good battery safety. Early Japanese electric vehicles had some applications; But its main disadvantage is that the battery has low specific energy and poor cycling stability. Currently, it is mainly used in the field of energy storage and is often mixed with ternary materials.

Ternary materials refer to lithium nickel cobalt manganese oxide, which can be regulated in terms of specific energy, cycling, safety, and cost. Nickel increases capacity and reduces cycling, cobalt increases stability and damages capacity, manganese reduces costs and improves safety, but damages the structure. Different configurations bring different performance. The focus of research and development is to find the proportion of materials and achieve the best comprehensive performance. Of course, there are also alternatives, such as replacing manganese with aluminum, which becomes lithium nickel cobalt aluminate. Ternary materials are mainly used in power batteries. Currently, ternary materials have become the sub field with the highest growth rate of positive electrode materials.

2. Positive electrode material

a. Lithium carbonate&lithium hydroxide

Monohydrate lithium hydroxide is a highly corrosive white crystalline powder, traditionally used in lithium based lubricants, glass ceramics, and petrochemicals. However, with the increasing demand for high nickel lithium batteries, battery materials have become the core driving force of the lithium hydroxide market.

Lithium carbonate and lithium hydroxide are similar lithium salts, both of which are lithium sources for producing positive electrode materials for lithium batteries and are located in the middle of the lithium industry chain for smelting and processing. The difference is that lithium hydroxide has strong corrosiveness and belongs to hazardous chemicals, making it more difficult to produce than lithium carbonate. At present, lithium carbonate is mainly used in the production of lithium iron phosphate and low nickel cathode materials in ternary materials (NCM111, 523, and some 622), while lithium hydroxide is mainly used in the production of high nickel cathode materials in ternary materials (some NCM622, all NCM811, 90505, and NCA).

b. Iron phosphate

Iron phosphate, also known as high iron phosphate or iron orthophosphate, with the molecular formula FePO4, is a white, off white monoclinic crystal powder. It is a salt formed by the interaction between iron salt solution and sodium phosphate, where iron is trivalent. Its main purpose is to manufacture lithium iron phosphate battery materials

Battery grade iron orthophosphate: purity ≥ 98.8% or greater than 99.5%, completely dehydrated, and stored in a dry state.

c. Ternary precursor

The ternary precursor is nickel cobalt manganese hydroxide, which can be divided into NCM811 precursor, NCM622 precursor, NCM523 precursor, and NCA precursor according to the different composition ratios of the elements. In the lithium battery positive electrode industry chain, the final performance of the positive electrode material will inherit the morphology and structural characteristics of its precursor, as well as the quality of the precursor (morphology, particle size, particle size distribution, specific surface area, impurity content, tap density, etc.)

Characteristic: Extremely smooth

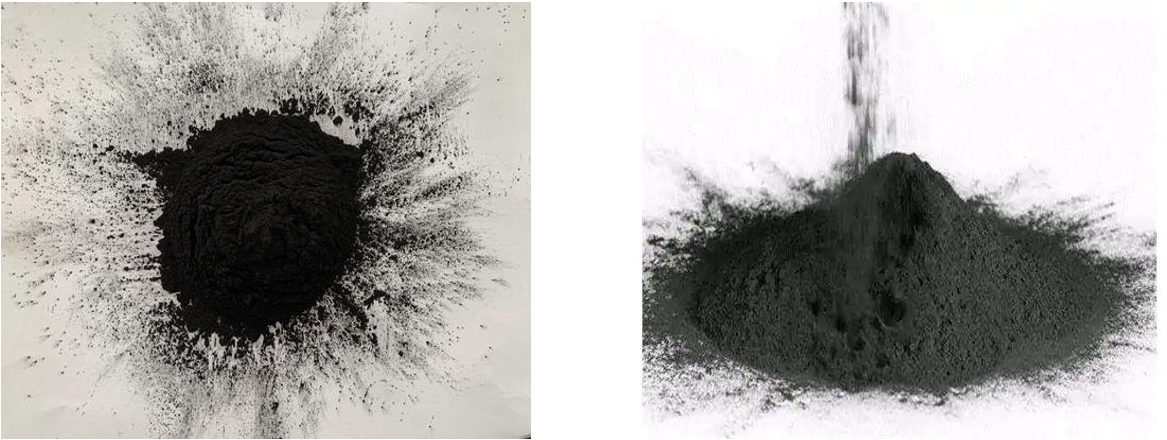

d. Cobalt trioxide

Cobalt trioxide, black or grayish black powder. Loose density 0.5-1.5g/cm3, tap density 2.0-3.0g/cm3. It is a product of cobalt monoxide and cobalt trioxide. Exposed to the air, it is easy to absorb moisture but does not form hydrates. When heated above 1200 ℃, it will decompose into cobalt oxide. When heated to 900 ℃ in a hydrogen flame, it is reduced to metallic cobalt.