2024-09-12

2024-09-12

Production precautions

1. Anti breakage bag

Package breakage is a serious functional customer complaint, and attention should be paid to:

a. The inner bag tape is evenly adhered

b. The matching degree of stitching between the outer and inner bags should be reasonable in design, and the length and width of the inner bag should be within the correct tolerance as much as possible.

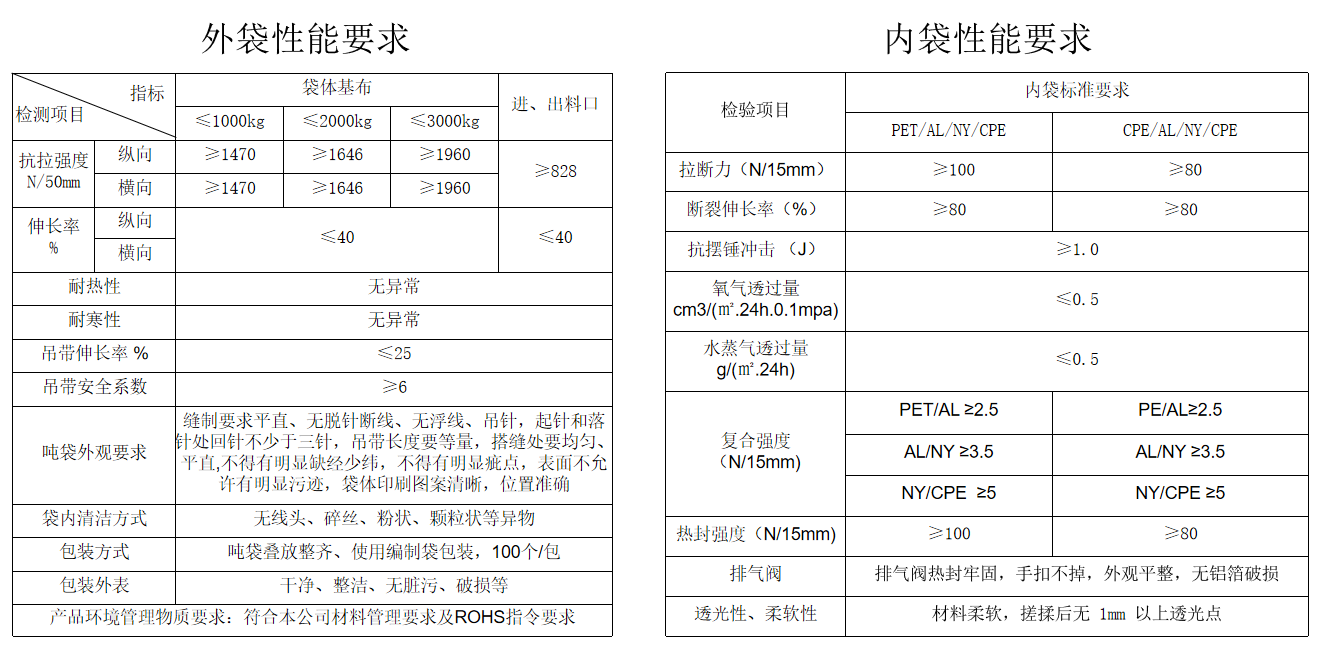

c. Inner bag composite strength, no delamination, air leakage, or rupture allowed

Please note that each layer of the inner bag is laminated using a dry laminating machine, and the curing time is not less than 48 hours.

2. Prevent the infiltration of foreign objects and trace elements

Excessive foreign objects and trace elements are extremely serious safety complaints. Due to the continuous production of crystals during the use of lithium batteries, if trace elements exceed the standard, there is a high probability that the crystals will puncture the battery separator, causing the positive and negative poles of the battery to short-circuit, resulting in fire or explosion.

Trace elements mainly control various types of metal elements. Common metal elements include copper, iron, zinc, and aluminum, which are materials that appear in our production workshop. The metal elements that appear in the outer bag workshop are mainly iron and zinc (machine and needle)

Control of foreign matter and trace element infiltration prevention

a. The production of inner bags needs to be carried out in a 100000 level dust-free workshop (lower limit), and the machine needs to be treated (sprayed or wrapped with plastic)

b. The demagnetization in the production process of inner bags mainly involves tying magnetic rods under forklifts to adsorb metal foreign objects on the ground, and sweeping the materials in and out of the workshop with magnetic rods to remove metal foreign objects on the surface of the materials. Use a magnetic rod to clean and absorb metal foreign objects on the machine for bag making and material replacement.

c. After the outer bag is formed, it needs to pass through a metal detector under a fluorescent lamp to eliminate the possibility of needle breakage inside the ton bag

d. If possible, it is best to produce the outer bag in a dust-free workshop, and the outer bag forming workshop is completed on plastic pallets, with the woven fabric material not touching the ground throughout the entire process.